Recent News

UNM Engineering team wins ASEE best paper for work on first-year engineering course

July 17, 2025

New director will enhance interdisciplinary engineering learning opportunities

July 2, 2025

Final SIRI cohort visits UNM campus

June 30, 2025

Perfetti receives ANS Landis Engineering Achievement Award

June 26, 2025

News Archives

UNM Civil Engineering Demonstrates Flood Control Model

September 7, 2011

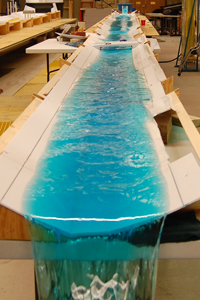

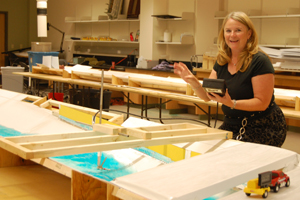

The demonstration started with just a trickle of water meandering down the 65’ channel, then quickly accelerated to a modeled flow of 24,000 cubic feet per second. The blue-tinted water rushed along, gushing over the channel’s sides in some places, simulating a flood along the North Diversion Channel. It was exhilarating to watch, and UNM Civil Engineering Professor Julie Coonrodwas in her element.

The demonstration started with just a trickle of water meandering down the 65’ channel, then quickly accelerated to a modeled flow of 24,000 cubic feet per second. The blue-tinted water rushed along, gushing over the channel’s sides in some places, simulating a flood along the North Diversion Channel. It was exhilarating to watch, and UNM Civil Engineering Professor Julie Coonrodwas in her element.

The Hydraulics Lab in the basement of the Centennial Engineering Center is Coonrod’s water playground and research focus, where she builds physical models of storm water structures primarily to help the Albuquerque Metropolitan Arroyo Flood Control Authority (AMAFCA) alleviate flooding, prevent injury or loss of life, and eliminate or minimize property damage.

Her most recent project is to examine the potential impact of stormwater conveyance in the North Diversion Channel if bike notches (recessed bike paths) are placed under the Singer and Osuna Bridges. The North Diversion Channel was built by the Corps of Engineers in the 1960’s, and while AMAFCA maintains it, the Corps must approve any changes made in the channel.

Her most recent project is to examine the potential impact of stormwater conveyance in the North Diversion Channel if bike notches (recessed bike paths) are placed under the Singer and Osuna Bridges. The North Diversion Channel was built by the Corps of Engineers in the 1960’s, and while AMAFCA maintains it, the Corps must approve any changes made in the channel.

The Osuna Bridge is particularly interesting, as the bridge abutments extend into the channel just downstream of the Bear Arroyo confluence. Coonrod’s work has shown that the proposed bike notches will not affect the stormwater conveyance.

This is the 23rd year that UNM has been under contract with AMAFCA supporting research as well as funding for graduate students like Kareem Saint-Lot.

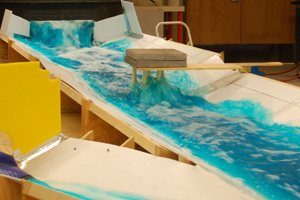

When a group from the Army Corps of Engineers recently came to the lab for a demonstration, they pointed out that Coonrod’s model showed an ideal-case scenario for the flooding. They brought up two issues: a hand rail on the trail could get clogged with debris, rendering the area of the bike notch ineffective for carrying flow, and the effect of debris and sediment in the flow should be considered. Coonrod and her team built long vertical panels simulating a worst-case scenario of a clogged hand rail. They also used sections of wire screens to simulate increased roughness in the channel due to debris and sediment.

Coonrod’s team takes velocity measurements in the channel to make sure the flow properties are scaled properly. The simulated 500-yr storm still cleared the bridges and remained in the channel, assuring the Corps that the bike notches would not compromise the flood conveyance properties of the channel.

Coonrod’s team takes velocity measurements in the channel to make sure the flow properties are scaled properly. The simulated 500-yr storm still cleared the bridges and remained in the channel, assuring the Corps that the bike notches would not compromise the flood conveyance properties of the channel.

Coonrod and her students typically build a couple models each year for AMAFCA. Recent models have included the South Diversion Channel Best Management Practice and the Hahn Arroyo Improvements, both being constructed in Albuquerque currently. AMAFCA estimates that lab experiments have saved them millions of dollars. It’s much easier to alter a scaled design of wood, plastic, and metal than it is to alter the large reinforced concrete structures in the field.

Coonrod and her students typically build a couple models each year for AMAFCA. Recent models have included the South Diversion Channel Best Management Practice and the Hahn Arroyo Improvements, both being constructed in Albuquerque currently. AMAFCA estimates that lab experiments have saved them millions of dollars. It’s much easier to alter a scaled design of wood, plastic, and metal than it is to alter the large reinforced concrete structures in the field.