Recent News

New director will enhance interdisciplinary engineering learning opportunities

July 2, 2025

Final SIRI cohort visits UNM campus

June 30, 2025

Perfetti receives ANS Landis Engineering Achievement Award

June 26, 2025

Engineering a new treatment for ovarian cancer

June 24, 2025

News Archives

UNM mask making operation moves to Centennial Engineering Center

June 29, 2020 - by Kim Delker

After two months of around-the-clock mask making at the COSMIAC research facility south of campus, The University of New Mexico’s 3D-printed mask production for the community and medical workers involved in the COVID-19 pandemic has moved to main campus for the summer.

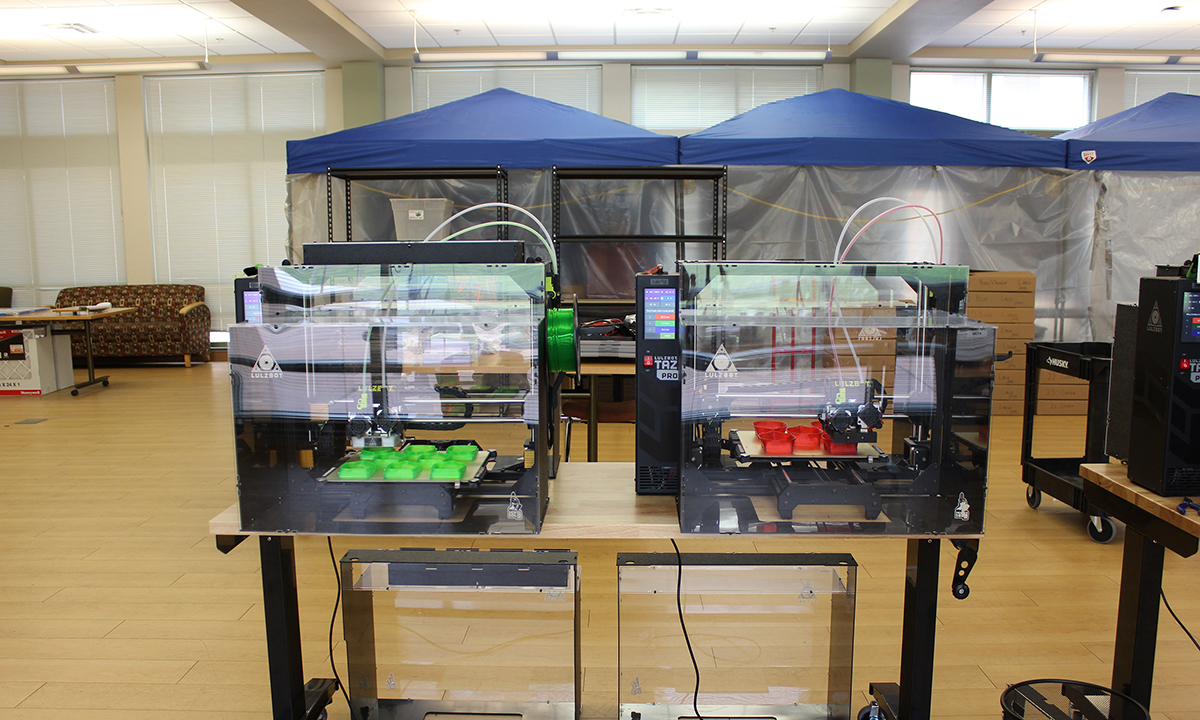

With laboratories beginning to open back up, the COSMIAC facility — a space-related research lab affiliated with the School of Engineering — needed to utilize its space and people to work on regular research projects, so the 3D mask production began moving to Stamm Commons in the Centennial Engineering Center the week of June 22.

Christina Salas, who has been in charge of the School’s mask production efforts, said that at full capacity, the COSMIAC operation was running about 12 3D printers, producing about 500 masks a week. With the move to Centennial, and the need for COSMIAC to reallocate some printers to space-related research, they have about half the number of printers during the summer as the group tries to keep up with the continuing demand caused by the pandemic.

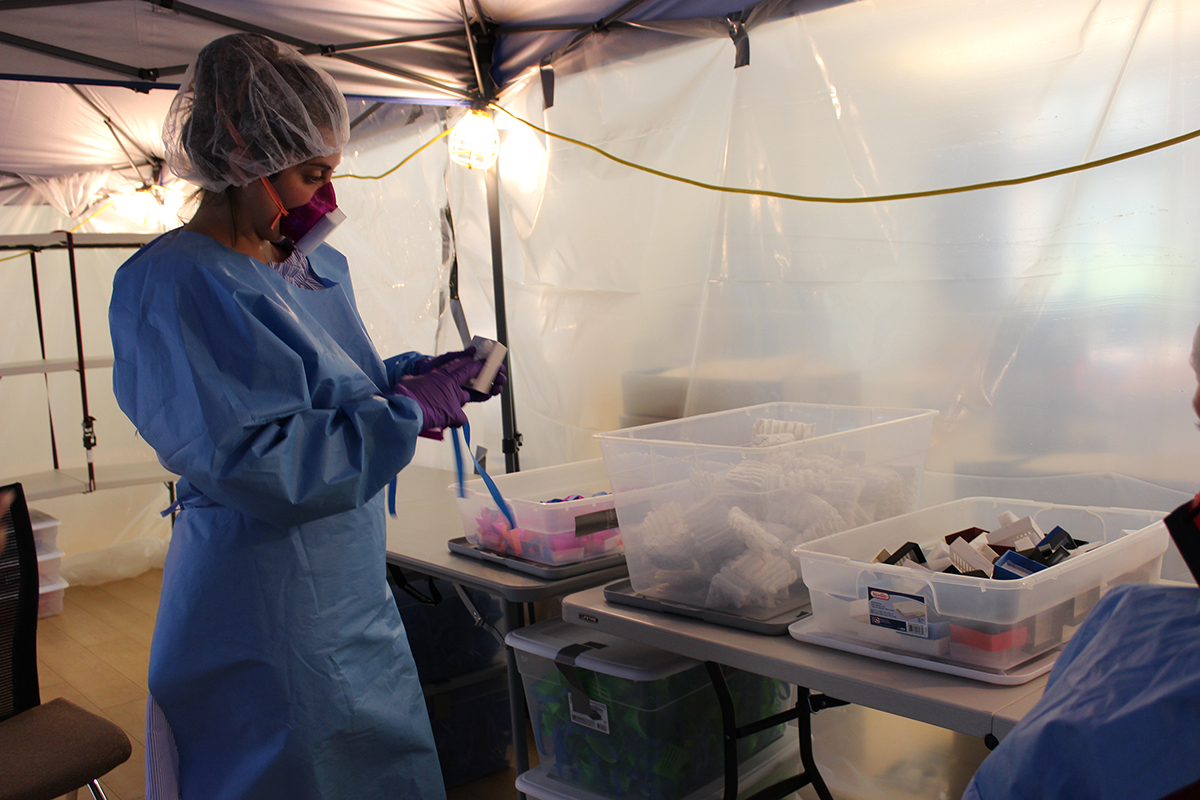

In addition, the cleanroom facility that had been co-located at COSMIAC was moved to the Stamm space as well. In that space, volunteer healthcare workers, led by flight nurse Laura Kief Shaffer, assemble, sanitize and vacuum seal the masks before they are distributed.

As of late June, nearly 4,000 masks and 2,500 face shields have been produced by the group for frontline workers and residents around the state, including some of the hardest-hit areas like Gallup and the Navajo Nation.

Salas, an assistant professor of the Department of Orthopaedics & Rehabilitation at UNM and special assistant to the dean of the School of Engineering for Health Sciences Center relations, said that the group is still getting a lot of requests for masks, both inside UNM as research labs open up and preparations are being made for fall classes, and outside UNM, for emergency workers, medical professionals, and communities in the northwestern region of our state.

In late April, the School of Engineering signed an agreement that streamlines the process so that masks produced at UNM are distributed to those in need with full support and oversight from the New Mexico Department of Homeland Security. In early May, the UNM 3D Mask Makers (a designation given to the team used by the PPE making community) partnered with the New Mexico COVID-19 Emergency Supply Collaborative to increase distributions, to get a better understanding of the needs of people in the state, and supplement their mask distributions with sanitizer, gowns, food, and water for the hardest hit communities.

Although the effort has received funding, initially from a grant from the U.S. Space Force, due to the constant demand for thousands of masks, Salas said the effort is now completely dependent upon donations. Specifically, they are hoping to use donated funds to replace 3D printers lost to space-related activities which will enable them to keep up with ever increasing demand for the masks.

The UNM Foundation has created a dedicated fund for the effort. In addition, the dean of engineering has designated that the School of Engineering’s Fund for Academic Excellence prioritize projects related to the pandemic. All donations made to this fund from March 15, 2020, until the end of the pandemic will be prioritized to support students, faculty and research that is deemed crucial in combating this crisis and helping our students thrive.